Human power technology evolved rapidly in the 19th century, with the advent of the steam engine at the beginning of the 19th century providing an adequate foundation for industrialization and early transportation, and the birth of the internal combustion engine at the end of the 19th century further revolutionizing the form of power technology and revolutionizing transportation on land, water, and in the air.

The invention of the internal combustion engine has had an impact everywhere, shaping every aspect of our modern lives. Despite its ubiquity in modern life, the basic concepts and knowledge associated with it may still be unfamiliar to many people.

In this article, we will introduce some of the common basics of the internal combustion engine to help readers who still have a vague understanding of what an internal combustion engine is.

What is an Internal Combustion Engine?

An internal combustion engine is a heat engine that converts internal energy into mechanical energy through the combustion of fuel. Unlike an external combustion engine, which requires external combustion and then transfers the energy, an internal combustion engine releases the energy directly inside the cylinders, which then drives the pistons and provides the corresponding mechanical power.

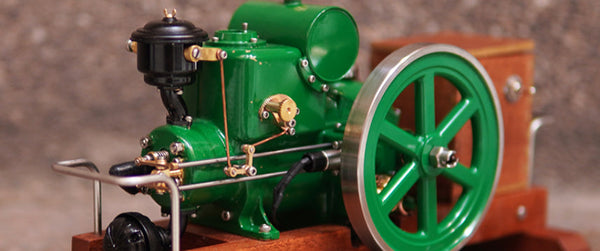

Because of the advantages of compact structure, relatively light weight, high output power and easy operation, internal combustion engines are widely used in life and industry.

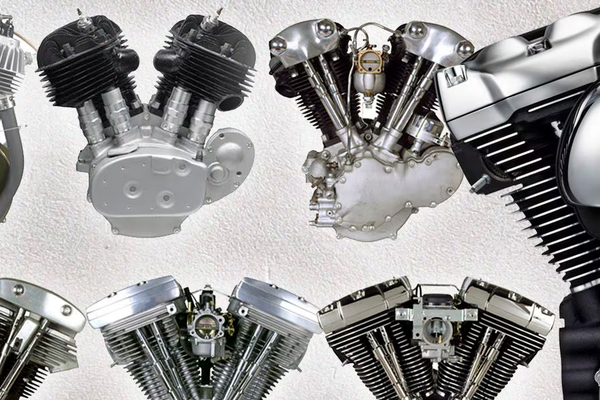

Especially in the field of transportation, the internal combustion engine is an indispensable core power, including automobiles, motorcycles, airplanes, ships and other types of equipment, all use the internal combustion engine as an important power source.

For a long time, the internal combustion engine virtually defined the “motorized society,” making it easier for individuals to get around and allowing global trade and logistics systems to develop rapidly. Even in today's environment of new energy technologies, the internal combustion engine still plays an important role in many areas.

How Internal Combustion Engine Work?

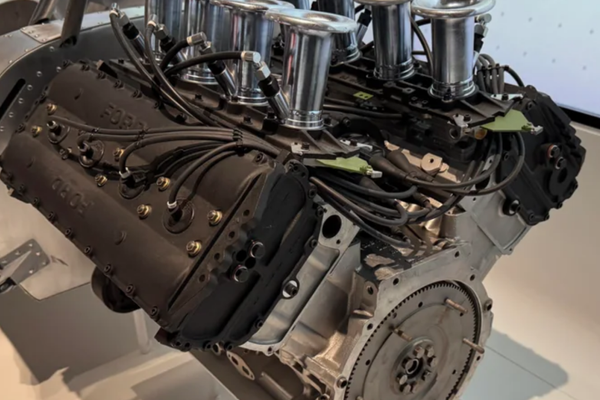

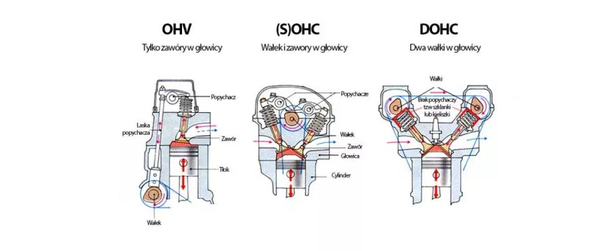

An internal combustion engine consists of many different parts, including core components such as cylinders, pistons, crankshafts, valves, and spark plugs, that work together through the energy released by combustion.

In an internal combustion engine, the process of ignition and combustion of fuel takes place inside the engine. The engine consists of cylinders and pistons that form the basic structure.

The expanding gases after combustion drive the pistons to move, which in turn drive the crankshaft to rotate, and the crankshaft transmits the movement through the power transmission system (including clutches and gears), so that a series of chemical energies generated by the combustion of the fuel are transformed into kinetic mechanical energies to drive the vehicle or mechanical equipment.

In order to accomplish these energy transformations in an orderly and efficient manner, most internal combustion engines utilize a four-stroke cycle, which means that four piston strokes are required in a single combustion-generating operating cycle.

The cycle consists of four strokes - intake, compression, power stroke and exhaust - and the specifics of what happens in each stage are explained in detail below:

-Intake stroke: At the beginning, the piston moves downward, leaving the cylinder in a state of vacuum, and air is drawn in and mixed with the fuel to become a fuel-air mixture and enter the cylinder.

-Compression stroke: the piston in the cylinder moves upward to compress the fuel-air mixture.

-Power stroke: the ignition system of the spark plug ignites the fuel-air mixture and generates an explosive combustion releasing energy, the resulting power stroke pushes the piston downward and correspondingly generates mechanical kinetic energy.

-Exhaust stroke: Finally the top exhaust valve opens and the exhaust gases are discharged through this valve.

These four strokes are repeated over and over again, allowing the engine to continue to produce mechanical kinetic energy for the reliable and stable operation of the vehicle or mechanical device.

Types of Internal Combustion Engine

Based on the core differences in fuel-air mixing, ignition, and power output structure, internal combustion engines are classified into three main types, each of which has its own characteristics and applications:

Gas engines (gasoline engines), commonly found in automobiles, motorcycles, or small machines, are also known as spark-ignition gasoline engines because their core feature is spark ignition.

In a spark-ignition engine, fuel and air are mixed and drawn into the cylinder through the intake stroke, the piston then compresses the fuel-air mixture, and finally a spark plug ignites the mixture, causing combustion.

The high-pressure gases produced by combustion expand rapidly and push the piston downward to complete the power stroke, thus delivering mechanical energy.

-Diesel Engines

Diesel engines have long been the centerpiece of heavy-duty vehicles, construction machinery and ships.

The principle of operation is very different from that of a gasoline engine. In a diesel engine, the intake air is highly compressed and fuel is injected directly into the hot compressed air to ignite and burn it.

The fuel is injected directly into the hot compressed air, which ignites and burns it. This method of operation does not require spark plugs, and is mainly a compression ignition, which is why diesel engines are also known as compression-ignition diesel engines.

-Turbine Engines

Turbine engines are widely used in aviation, power generation, etc. Unlike gasoline and diesel engines, turbines do not have pistons, so their principle of operation is to utilize a continuous flow of air or combustion gases.

In a turbine, air is continuously compressed, and when fuel is injected and ignited, it burns rapidly to produce high-pressure gas that flows through the turbine blades and drives them to rotate at high speed, so that the resulting rotary motion is used to drive the engine or generate electricity.

The lack of a reciprocating piston makes turbine engines extremely smooth, which, combined with their compactness and high power-to-weight ratio, enables them to play an important role in aerospace and power generation, where precision and reliability are essential.

0 Kommentare